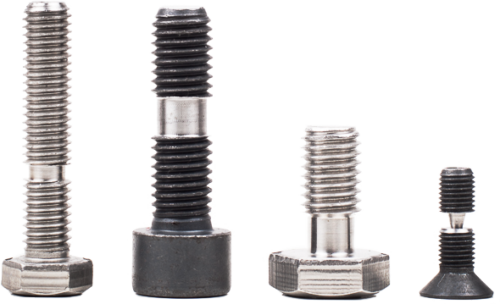

If standard screws no longer meet your application’s demands, we will provide the appropriate special screws. We can also make numerous adjustments to standard parts:

- Shortening the screw head or bolt length can be an option if a standard fastener would protrude out of the components to be fastened.

- If design constraints do not leave enough space for a standard screw head, we can reduce the head diameter.

- We can meet special safety requirements by inserting a groove in the thread or wire hole into bolts to prevent them from coming loose.

In the manufacture of special screws, we equip our CNC lathes manually to guarantee top precision and flexibility for your project.

Our customers either supply the feedstocks themselves, as most wholesalers do when we manufacture special screws on commission, or we can take care of the complete production, from blanks procurement to surface finishing, if they order finished products, as most plant or machine manufacturers do.

![Giso Meier [EN]](https://en.gisomeiergmbh.de/wp-content/uploads/2018/07/sonderschrauben-header0.jpg)