Special screws: just what you need

Meeting precise specifications: two examples

Our focus on “special screws” has evolved from individual use cases. Here are two particularly impressive examples of how we can turn your precise specifications for the desired function of the required special screw into a working solution.

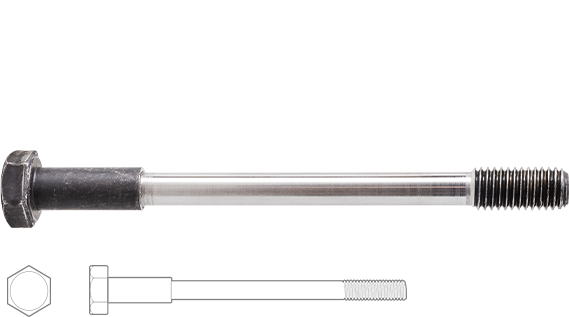

Special screws in short production runs up to single pieces.

Your desired special screw is not available anywhere? From Giso Meier, it is!

A Harley-Davidson is a real eye-catcher – a special screw for such a machine needs to meet aesthetic and functional requirements, without any compromise. Our customer wanted an elegant way of attaching a saddlebag of his own design to the fender mount of his Harley-Davidson.

We designed a stylish solution: a double-threaded screw with two different inch threads that is as striking as it is rare, making his wish come true. Our customer commented: “This screw is awesome!” And we tend to agree.

Accurate and precise:

special screws for world champions

Designed, manufactured and delivered on schedule: With clicker screws from Giso Meier, two archers of Germany’s national team became vice world champions at the mixed world championship in Mexico.

In collaboration with shooting equipment manufacturer TEC-HRO, we have developed precision clicker screws for their MicroClicker. These special screws are used in archery not only by competitive athletes, but also by sport shooters in clubs to adjust the target.

Special material requirements: The special screws had to be both light and strong, so we decided to use aircraft aluminium, which was anodised in black for decorative purposes.

From samples to pre-series to serial production

We are looking forward to your test order

Usually, we will manufacture a small quantity of about 10 pieces as a pre-series run before the actual production run. This allows our customers to check and approve the parts before we produce the desired series of a few hundred up to 10,000 pieces.

For thin shank screws, we offer our customers to place a test orderof, for example, 200 pieces, before they decide to place their series order of several thousand screws. We also manufacture small serie, samples and pre-series exactly according to your requirements.

For your first test order, you can use our contact form where you can also attach a drawing and tell us the specific requirements for YOUR special screw.

A sign of confidence from our regular customers: “No need for a pilot production.”

Our returning customers know that they can rely on special screws made by Giso Meier – they do no longer consider prototypes or pre-series necessary and simply send us their drawings with a series order.